what is compressive test|how to calculate compressive strength : exporter exporters exporting Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using . On Funyo you may participate in random video conversations without having an account, which is one of our key advantages. By clicking “start chatting” and turning on your webcam, you can talk to strangers online. Once you begin, you will link to thousands of people who wish to video chat with you worldwide. Using your camera in real-time .

{plog:ftitle_list}

The media frenzy around the killings push Kabir and team to the brink. Through this, Kabir painstakingly connects the dots and lands a vital lead that threatens Avinash's mission to .

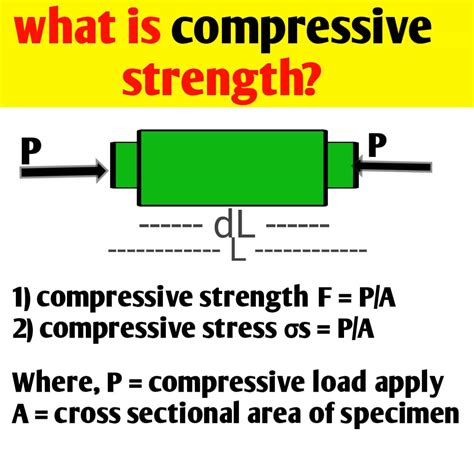

Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using .A compression test is a mechanical test that determines how a material such as aluminum or plastics behaves under a compression or crush force. The output of a compression test is a test report that characterizes compressive .A compression test is conducted in a manner similar to a tensile test except that the force is compressive and the specimen contracts along the direction of stress. Equations (1) and (2) are used to compute compressive stress and strain, respectively. By convention, a compressive force is taken to be negative, which yields a negative stress.Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted .

A compression test is a common method used in this process, and multiple compression tests can provide even more insight into a material’s strength and durability. Materials that undergo compressive testing include: Compression testing is a key part of basic materials characterization. This video discusses the equipment used when performing a compression test and explain.

2. Common compression test definitions and keywords. Common compression test definitions and keywords include the following, which will be introduced to you below: Compressive Strength: After gradual compression, the maximum compressive stress a material can sustain before yielding or breaking. Force per unit area is used to measure .

In the compression test, a standardized specimen is loaded under compressive stress until it breaks or until a first crack appears. The testing of materials under compressive stress is carried out in the so-called compression test.Standardized round specimens are used, which are much thicker than tensile specimens.The maximum height of the sample is twice the . Attach the compression test adapter into the cylinder nearest the front of the engine, then connect the gauge to the other end of the adapter hose. To perform the test, crank the engine 4 times by turning the key in your car’s ignition, then check the compression gauge for the result. After you get a result for the first cylinder, repeat the . A compression test is a type of mechanical testing that measures a material’s behavior under applied forces, usually conducted by applying pressure on a test specimen using platens or fixtures. Compression strength tests measure a material’s behavior under applied forces to determine its maximum stress capacity. Compression TestThe compression test works by spinning the engine through its cycles with the compression tester in place of the spark plug in the cylinder. As the engine makes pressure, the gauge .

Purpose [edit | edit source]. The Sacroiliac Joint (SIJ) Compression Test or “Approximation Test” is a pain provocation test which stresses the SIJ structures, in particular, the posterior SIJ ligament, to attempt to replicate patient’s symptoms (Laslett and Williams; 1994) . Technique [edit | edit source]. The patient is in side lying and the examiner's hands are placed over the upper .Materials such as concrete and rock are often evaluated using a compressive strength test and, in these cases, fracturing occurs. Materials such as steel can also be tested for compressive strength, and in the case of ductile materials, deformation tends to occur. Initially, a ductile material will accommodate the applied load by adjusting its .Composite compression testing methods provide a means of introducing a compressive load into the material while preventing it from buckling. Compression tests are performed for composite materials that are in the form of a relatively thin and flat rectangular test specimen such as laminate panels.Compression testing measures how much force is needed to deform or compress a material under compression loads. During this test, the sample is placed into a compression testing machine, which applies a constant load until a pre-determined amount of defamation is reached, or the point of fracture. Compression testing determines essential .

Unconfirmed Compressive Strength (UCS) stands for the maximum axial compressive stress that a specimen can bear under zero confining stress. Due to the fact that stress is applied along the longitudinal axis, the Unconfined .

The compressive strength test has multiple objectives, including: To assess the quality of concrete in relation to the specifications for a particular project. To gauge the potential load-bearing capacity of a concrete sample, .The compressive strength is usually obtained experimentally by means of a compressive test where uniaxial compressive load is applied till its failure. Sobolkina et al. [19] investigated the dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix with specimen preparation details shown in Table 1 .Compression of wood and wood-based materials plays an important role in almost any construction projects. If the compression strength or bending strength of a 2-inch by 4-inch beam is not known, deflection due to bearing a load may cause significant deformation, which could even lead to its failure during service life. . which can be . Simulation 7: FEM simulation of a compression test This page titled 5.7: Compression Testing - Practical Basics, Friction and Barrelling is shared under a CC BY-NC-SA license and was authored, remixed, and/or curated by Dissemination of IT for the Promotion of Materials Science (DoITPoMS) via source content that was edited to the style and .

Compression testing is a very common testing method that is used to establish the compressive force or crush resistance of a material and the ability of the material to recover after a specified compressive force is applied and even held over a defined period of time.Compressive strength is an essential property in structural materials, for example, mortar, which comprises the interacial transtition zone in concrete, stone, and steel, since material design is normally evaluated in terms of the risk of compression failure. In addition the CBM is known as having strength for compression force. Therefore plenty of standard tests exist to measure the . A compression test measures a cylinder’s ability to hold pressure as the piston moves up and down. Mechanics use an oscilloscope and observe the stored pattern as the engine spins when performing a dynamic compression test. Regular engine misfires, reduced acceleration, and poor fuel economy are indicators that you need to conduct an engine . Doing a compression test, is a good way to measure the condition of, the rings, cylinders, and valves. So, if your engine is running rough or is lacking power, consider doing a compression test. Also, it is important to perform a compression test every time a tune-up is done, as part of preventative maintenance.

How do you test the compressive strength of concrete? Testing is the only way to determine whether a concrete mix has enough compressive strength, or load-bearing capacity, for the intended use. These tests are conducted on cylindrical concrete specimens (per ASTM C39 ) using a machine that compresses the cylinders until they crack or break . 4. Pullout Test (ASTM C900) Method: The main principal behind this test is to pull the concrete using a metal rod that is cast-in-place or post-installed in the concrete. The pulled conical shape .

One thing that the wide range of compression test methods have in common is the use of a very short gauge length. Typical gauge lengths for compression samples are 10-13mm, although they can go as low as 5mm. In comparison, the typical gauge length of a tensile specimen is around 160mm. This is due to the requirement to minimise a premature .

Compression testing, like tensile and bending tests, is a fundamental mechanical test. Compression tests are used to characterize the strength and stiffness of a material or product when subjected to crushing loads. Compressive tests are performed by placing a specimen under pressure with platens or specialized fixtures on a testing machine .

custom multimeter s moisture meter

what is compressive strength test

how to do a compression test on car engine

Resultado da Molde FK Sub 19. 18 NOV 2023. UEFA Youth League. AZ Alkmaar Sub 19. 08:00. Molde FK Sub 19. 28 Nov 2023. Confira todo o calendário de .

what is compressive test|how to calculate compressive strength